Unilok tube fittings are single-ferrule compression fittings that provide leak-tight and remarkable connections in process and analytical instrumentation, control systems, utilities, and other applications.

Quick Links

- Select Unilok Fittings

- Unilok Tube Fittings Catalog

- Pressure Rating Tables

- How to Order

- Warranty

- Safety Information

Specifications

- MAWP: 12,000 psig*

- Temperature Range: -325 to 1200°F

- Materials: 316 SS, Alloy 400, C-276, and brass. Other materials are available.

- Sizes: 1/16 to 1 in.

- Adapters: NPT, ISO/BSP, SAE/MS, AN, weld, tube stub, port connectors, and ORFS.

- Shapes: Straight, elbows, tees, crosses, caps, plugs,

- Special fittings: Bulkhead and extended (long), bore through, positionable, calibration and dielectric fittings, silver plated nut.

- Accessories: Stop collars, bulkhead locks, nut and ferrule sets, prewrapped thread, tools and accessories

*Unilok tube fittings are rated to the maximum allowable pressure rating of the tubing they connect.

Unilok Technology

To provide a reliable, leak-proof connections in instrumentation and process tubing systems, Unilok tube fittings consist of three precision-machined components: body, ferrule, and nut. The single ferrule design, with the spring-like action of the ferrule during make-up, compensates for the variation in tubing materials, hardness, and thickness of the tube wall to provide leak-tight connections in an extensive range of application.

Through the critical interaction of the precisely machined fitting components with the process tube, a leak-tight seal is achieved. The simple geometric rotation of the Unilok nut provides the axial thrust necessary to coin the ferrule to the outside diameter of the tube. To eliminate any potential stress on an existing system, they have been designed not to transmit installation torque from the fitting to the tubing.

During the rotary movement of the nut, the internal surface of the nut meets with the rear surface of the ferrule to axially move the ferrule forward into the angular section of the fitting body. The leading edge of the ferrule is directed into the tube to begin the required “bowing” action of the ferrule.

Subsequently, the leading edge of the ferrule “locks” on the outside diameter of the tube to complete the sealing action and secure the tube within the fitting. The resulting “spring-like action” of the ferrule is designed to help compensate for exposure to system variables such as vibration.

Design

To provide reliable, leak-proof connections in instrumentation and process tubing systems, Unilok tube fittings consist of three precision-machined components: body, ferrule, and nut. The single ferrule design, with the spring-like action of the ferrule during make-up, compensates for the variation in tubing materials, hardness, and thickness of the tube wall to provide leak-tight connections in an extensive range of applications.

Through the critical interaction of the precisely machined fitting components with the process tube, a leak-tight seal is achieved. The simple geometric rotation of the Unilok nut provides the axial thrust necessary to coin the ferrule to the outside diameter of the tube. To eliminate any potential stress on an existing system, they have been designed not to transmit installation torque from the fitting to the tubing.

During the rotary movement of the nut, the internal surface of the nut meets with the rear surface of the ferrule to axially move the ferrule forward into the angular section of the fitting body. The leading edge of the ferrule is directed into the tube to begin the required “bowing” action of the ferrule.

Subsequently, the leading edge of the ferrule “locks” on the outside diameter of the tube to complete the sealing action and secure the tube within the fitting. The resulting “spring-like action” of the ferrule is designed to help compensate for exposure to system variables such as vibration.

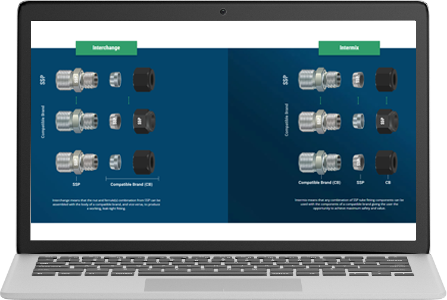

Interchange and Intermix

Unilok®, our single-ferrule tube fittings , can intermix with Parker CPI™ fittings to provide reliable, leak-proof connections in instrumentation and process tubing systems, provided they are used in accordance with SSP Fittings' published installation and service recommendations.. They can withstand pressures of up to 12,100 psig* and a temperature range of -425 °F to 1,200 °F. You can learn more about our interchange and intermix products here.

*Unilok tube fittings are rated to the maximum allowable pressure rating of the tubing they connect.

Materials

Unilok tube fitting straight configurations are machined from type 316 stainless steel cold-finished bar stock in accordance with ASTM A-276 and ASTM A-479. Tube fitting shapes, elbows, tees, and crosses are machined from close-grained 316 stainless steel forgings in accordance with ASTM A-182. All 316 stainless steel. Unilok components are heat code traceable with certified material test reports (CMTRs) available on request.

Packaging

Unilok tube fittings are individually bagged to ensure the highest quality, safety, and cleanliness levels. They are also packaged in small-lot quantities. Boxes are labeled with product photos, body material, and part numbers. Product installation instructions are included in each box.

Quality Certification

Unilok tube fittings are manufactured in accordance with SSP’s Quality System, which has been certified to conform to the ISO 9001:2015 Quality Standard. In addition, all Unilok tube fittings are manufactured to the technical design specifications and rigid quality control standards of the SSP Instrumentation Division. SSP’s continuing commitment to quality is reflected throughout the company in its personnel, policies, equipment, products and service.

Approvals and Test Reports

Unilok tube fittings have been tested and/or approved in accordance with the standards of the following organizations:

- American Bureau of Shipping

- Unilok Tube Fitting Interchange and Intermix Test Report

- CSA Report

- Unilok Technical Report

Tube Fittings Installation Training

SSP and SSP distributors provide extensive installation training. Courses cover:

- Intermixing and interchanging

- Swaging and quality assurance

- Remaking and reusing tube fittings

- Handling cutting and preparing tubing

- Tube bending

Tools and Accessories

SSP offers tools and accessories to support tube fitting assembly and installation and the tubing cutting, preparations and bending. More about tool and accessories.

Interchange

Interchange means that the nut and ferrule(s) combination from SSP can be assembled with the body of a compatible brand, and vice-versa, to produce a working, leak-tight fitting.

Intermix

Intermix means that any combination of SSP tube fitting components can be used with the components of a compatible brand giving the user the opportunity to achieve maximum safety and value.