SSP offers check valves for instrumentation, alternative fuels, and small process applications having pressures up to 6000 psig (413 bar) and temperatures from -100 to 900° F (-73 to 482° C) .

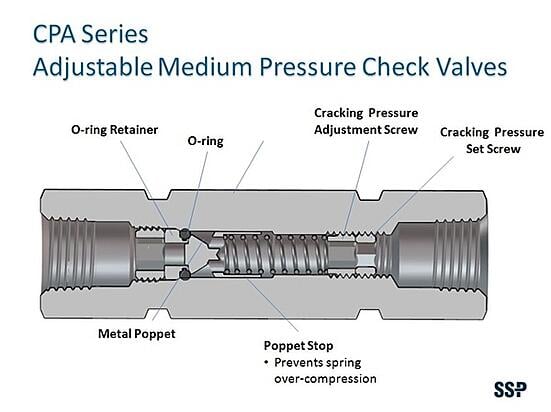

CPA Series Adjustable Check Valves

CPA Series check valves are pipe ended check valves that enable users to make field adjustments to cracking pressures to meet the requirements of their application.

The CPA Series check valves feature adjustable cracking pressures enabling instrumentation and process system designers and installers to fine tune cracking pressures to more precisely meet system requirements.

Select CPA Series Adjustable Check Valves for your applications.

Check Valve Specifications

- MAWP: Up to 3000 psig (206 bar)

- Temperature: -40 to 375°F (-40 to 190°C)

- Flow Coefficients: 0.35 and 1.20

- Body Materials: 316 SS, Alloy 400 and brass

- O-Ring Materials: Fluorocarbon FKM, Nitrile, low-temp Nitrile, ethylene propylene, and perfluorocarbon elastomer FFKM.

- Cracking Pressures: 3 to 50, 50 to 150, 150 to 350, and 350 to 600.

- End Connections: Male and Female NPT and BSPT

- End Connection Sizes: 1/4 and 1/2 in.

Features

Testing

Check valves are test with Nitrogen to confirm cracking and reseal pressures and for seat seal up to 1000 psig.

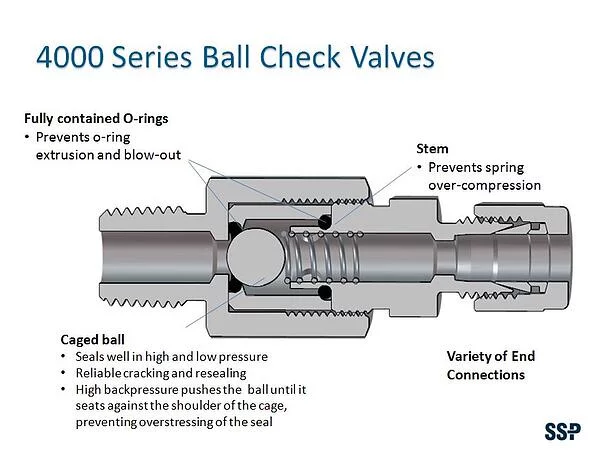

Ball Poppet Check Valves | 4000 Series

Ball poppet check valves are medium pressure instrumentation check valves. The ball poppet design reduces sticking for reliable cracking and resealing.

4000 series check valves are ball-poppet type check valves used to eliminate back flow or to maintain constant back-pressure in instrument, utility, and small process systems and equipment. The self-cleaning ball poppet design inhibits the poppet from sticking to the valve seat for more reliable cracking and resealing.

Select ball poppet check valves for your applications

Specifications

- MAWP: Up to 6000 psig (413 bar)

- Temperature: Up to 350° F (176° C)

- Body Materials: 316 SS

- Cracking Pressures: 1/3, 1, 5, 10, 15, 25, 50 psig

- Seat Material: Fluorocarbon FKM, and NBR

- Ball Material: 316 SS

- End Connections: Duolok, Griplok, Unilok tube ends, male and female NPT and BSPT and SAE pipe ends

- End Connection Sizes: 1/8 to 1/2 in. (6 to 12 mm Duolok only)

- Orifice Sizes: 0.09, .019, 0.28 in.

- Seven cracking pressures from 1/3 to 50 psi

- Wide range of O-Ring materials

Features

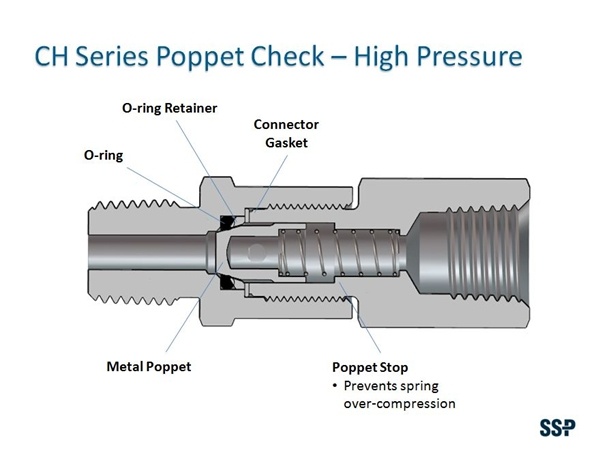

CH Series High Pressure Check Valves

CH Series check valves provide leak-tight control of back flow in instrumentation, alternative fuels, and small process applications where high pressure flow and cycle life are required. CH Series check valves are designed and tested to meet ECE R110 requirements.

Select CH Series high-pressure check valves for your applications.

Specifications

- MAWP: Up to 6000 psig

- Temperature Range: -65 to 400° F (-53 to 232° C)

- Flow Coefficient (Cv): up to 4.7

- Body Materials: 316 SS, Alloy 400 and Alloy C-276.

- O-Ring Material: Fluorocarbon FKM, Nitrile, Low-Temp Nitrile, Ethylene Propylene, and Perfluorelastomer

- Cracking Pressures: 1/3, 1, 5, 10, 15, 25, 50, 100 psig

- End Connections: Duolok, Griplok and Unlilok tube end, male and female NPT and BSP pipe ends, and SAE straight thread pipe ends.

- End Connection Sizes: 1/8 to 1 in. (6 to 12 mm Duolok tube ends only)

Features

Testing

CH Series check valves are 100% factory test for seal seal to 1000 psig (69 bar) and for cracking and realing pressure.

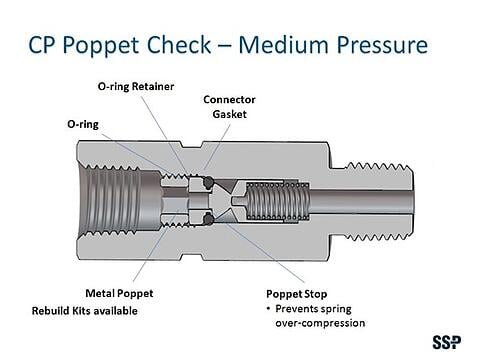

Poppet Check Valves

CP Series check valves are fixed cracking pressure, pipe ended check valves used to control back flow or to maintain constant back pressure. CP Series check valves are with factory set and and tested cracking pressurs up to 100 psig (6.9 bar).

Select CP Series Check Valves for your applications.

Specifications

- MAWP: Up to 3000 psig (206 bar)

- Temperature: -40 to 375° F (-40 to 190° C)

- Flow Coefficient: 0.35 and 1.20

- Body Materials: 316 SS, Alloy 400, and Brass. Other materials are available.

- Seat Materials: Fluorocarbon FKM, Nitrile, low-temperature Nitrile, Ethylene Propylene, and Perfluoroelastomer

- Cracking Pressures: 1/3 to 100 psig

- End Connections: Male and female NPT and BSPT

- End Connection Sizes: 1/4 and 1/2 in.

Features

Testing

Check valves are 100% factory tested with Nitrogen after assembly to confirm spring cracking pressure, and for seat leakage at 1000 psig.