SSP offers needle valves for instrumentation, controls, testing, laboratory, and other applications. Find Needle Valves for your applications.

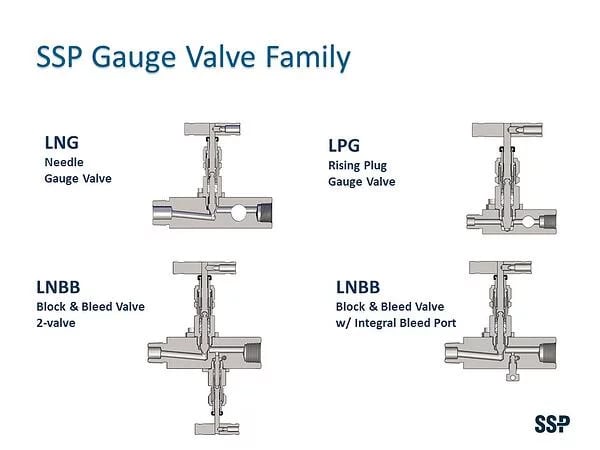

Needle Gauge Valves | Rising Plug Gauge Valves | Block & Bleed Valves

SSP offers needle and rising plug gauge valves in three port and block and bleed designs. Block and bleed valves are available with packed bonnet or non-packed vent valves. All packed bonnets feature live-loaded packing below the stem threads and non-rotating stems for better cycle life, lower maintenance and leak-tight shut off even in severe service conditions.

Specifications

- Temperature Range: -100 to 1200° F (-73 to 648° C)

- Pressure Range: up to 6000 psig (413 bar)

- Valve Orifice Sizes: 0.85

- Cv: 0.250

- Gauge Valve Types

- Needle Gauge Valves

- Rising Plug Gauge Valves

- Two-Valve Block & Bleed Valves

- Bleed Valve with Integral Bleed Ports

- Body Materials: 316 SS, Alloy 400 and Alloy C-276

- Packing Materials: PTFE, PEEK, Graphite

- Stem types: Non-rotating vee and Soft seal (PCTFE), regulating and metering

- End Connection Types: NPT, tube socket weld and pipe socket weld, male pipe,

Duolok®, Griplok® and Unilok® tube ends - End Connection Sizes:

- Inlet: 1/4, 1/2 and 3/4 in.

- Outlet: 1/4 and 1/2 in.

- Extended Inlets: 4 and 6 in.

Resources

- Select Gauge and Block & Bleed Valves for your applications.

- Download the LN Series Needle Valves Catalog.

- Download the LNBB/LNBP Locked Bonnet Gauge and Block and Bleed Valves Catalog

Features

Safer Bonnet Design

In the locked bonnet design, the bonnet is screwed into the valve body to seal on a metal to metal surface. The bonnet is locked in place with a ring, which is secured with a separate screw. This prevents accidental disassembly during packing adjustment, loosening due to vibration, or unscrewing of the bonnet by continuing to rotate the stem after it is fully open. The back-seating lower stem allows inline packing adjustments to be made more safely.

Better Non-Rotating Stem Tip Design

Unlike non-rotating ball stem tips, SSP gauge valves are designed with a non-rotating lower stem that prevents seat damage and reduces wear to the seat and packing. The threaded upper stem and stem pivot are located above the packing to prevent system media from attacking the threads, washing away thread lubricants or clogging, or corroding the non-rotating stem mechanism. This ensures that the stem tip will not rotate even in severe conditions.

Leak-Tight Reliability and Low Maintenance

The tighter your system, the better your data. SSP gauge valves are designed with live loaded packing that provides a dynamic leak-tight stem seal, which compensates for changes in pressure, temperature and packing wear.

Gauge Valve Types

LNG Series are 3-port needle gauge valves with LN Series isolation bonnets and three outlet ports. Non-rotating vee-tip stem provides a durable metal to metal seal. Soft seal PCTFE steel tips are also available.

LNBB Series are block and bleed valves featuring LN Series bonnets for both isolation and bleed functions to allow safer maintenance of instruments in systems with hazardous media.

LNBP Series are block and bleed valves featuring an LN Series isolation valve and an integral bleed port to allow maintenance of instruments having non-hazardous media.

LPG Series are rising plug 3-port gauge valves with LN Series isolation bonnets and three outlet ports. They feature a rising plug and soft seat design with a straight-through flow path that allows rodding

Options

Flexible Graphite Packing

PTFE packing is standard for LN Series valves. Flexible graphite packing is available for high-temperature applications.

Body Materials

- 316 Stainless Steel

- Alloy 400

- Alloy C-276

Lagging (Extended Inlet)

LN Series Gauge Valves and Rising Plug Gauge Valves are available with 4 in. lagging.

Tube End Connections

In addition to end connections offered in the Basic Part Number and Dimensions table, SSP can provide Duolok, Griplok and Unilok tube end connections.

Bleed Valves and Plugs

Bleed valves and pipe plugs can be ordered installed or shipped loose with gauge valves.

Special Cleaning

SSP Gauge valves are available cleaned in compliance with ASTM G93 Level C and CGA G-4.1, Cleaning Methods and Cleanliness Levels for Material and Equipment Used in Oxygen-Enriched Environments. To specify, add -XP98 to the part number.

For more information about other types of special cleaning, please contact your local SSP distributor or SSP Customer Service.

Sour Gas

Selecting valves for sour gas applications requires the consideration of several factors including the temperature, pH, partial pressure of H2S, and whether the application is

above or below ground. SSP offers four configurations to meet the requirements in NACE MR0175/ISO 15156-3 and NACE MR0103. To order gas for you application add the designator below to the part number.

Example: LNG6V-8PM-8PF-316-SG2

| Designator | Body Material | Wetted Parts1 | Non-Wetted Pressure Containing Parts |

|---|---|---|---|

| DesignatorSG1 | Body Material316 SS | Wetted Parts1Annealed 316 SS except body2 | Non-Wetted Pressure Containing Parts316 SS |

| DesignatorSG2 | Body Material316 SS | Wetted Parts1Annealed 316 SS | Non-Wetted Pressure Containing Parts316 SS |

| DesignatorSG3 | Body MaterialAlloy 400 | Wetted Parts1Alloy 400/UNS S20910 | Non-Wetted Pressure Containing Parts316 SS |

| DesignatorSG4 | Body MaterialAlloy 400 | Wetted Parts1Alloy 400/UNS S20910 | Non-Wetted Pressure Containing PartsAlloy 400 |

1Springs or other component may require other materials for

functionality.

2Compression fittings and valve bodies with compression fitting ports are exempt from lower hardness requirements per ANSI/NACE MR0175/ISO 15156 and NACE MR0103.

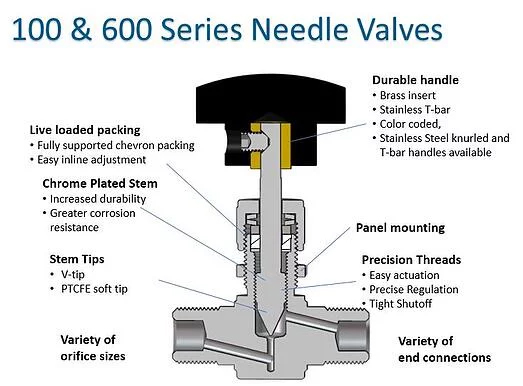

Needle Valves | 100 & 600 Series Integral Bonnet Needle Valves

100 & 600 Series needle valves have an integral bonnet design for instrument and general purpose applications. Live loaded chevron packing packing reduces the need for maintenance and packing adjustments making SSP needle valves suitable for high-cycle and dynamic temperature and pressure applications.

Specifications

- MAWP: Up to 6000 psig

- Temperature: -40° to 600°F (-40 to 315°C)

- Live-Loaded PTFE and PEEK chevron packing

- Stem Tip: Chrome-plated 316 SS vee-type and PCTFE soft-seal

- Body Materials: 316 SS, Alloy 400 and brass

- Straight and Angle Patterns

- End Connections Types: Duolok, Unilok, or Griplok tube end, NPT and BSPT pipe ends.

- End Connection Sizes: 1/8 to 1/2 in. (6 to 8 mm Duolok only)

Resources

Features

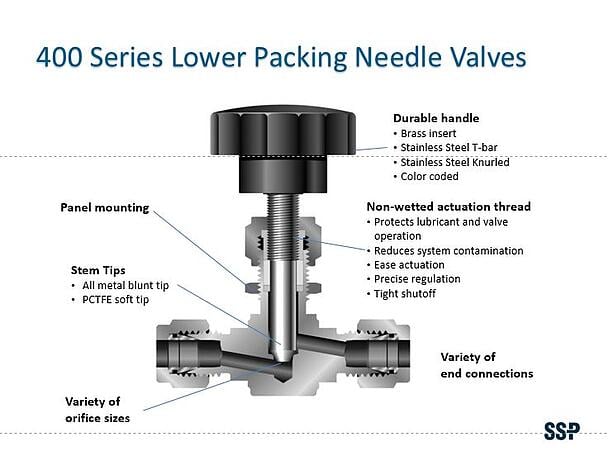

Needle Valves | 400 Series

400 Series lower packing needle valves provide positive shutoff for applications having working pressures up to 5000 psig. Lower packing needle valves feature packing below the stem threads to maintain stem lubrication and to protect stem threads from corrosive or erosive media. With orifice sizes up to 0.562 in. and end connections up to 1 in., 400 Series needle valves offer higher flow than other instrumentation needle valves.

Specifications

- MAWP: Up to 5000 psig

- Temperature: -40° to 450°F -40 to 232°C)

- Stem Tip: 316 SS V-Stem and PCTFE soft-seal

- Body Materials: 316 SS

- Straight and Angle Patterns

- End Connections: Duolok, Unilok, or Griplok tube fitting, MNPT and FNPT pipe fittings, and tube socket weld

- End Connection Sizes: 1/8 in. to 1 in.

Resources

Rising Plug Gauge Valves | LP Series

LP Series locked-bonnet rising plug and gauge valves are designed for the many severe servic applications in the oil & gas, chemical/petrochemical, and power industries where high vibration, temperature and pressure changes are common.

LP Series Rising Plug valves use a unique set of features that can improve reliability and reduce the operating costs for process instrumentation applications with working pressures up to 6000 psig (413 bar) and temperatures from -65 to 600° F (-53 to 315° C).

Features include:

- Live loaded chevron packing compensates for packing wear and changes in temperature and pressure; this design maintains a leak-tight stem seal and reduces or even eliminates the need for packing adjustments.

- Easily accessible packing adjustment and back seating stem tips make inline packing adjustments faster and safer.

- 17-4 hardened stem threads above the packing provide durability and ensures that the valve operates smoothly even in sever applications.

- Dust cap prevent infiltration from the environment.

- Bonnet locks prevent the accidental disassembly of the bonnet during maintenance, operation or from system vibration.

- Non-rotating lower stems reduce packing, seat, and stem damage that can result from the stem tip rotating onto the valve seat.

- Stem pivot above the packing ensure that the stem will not be infiltrated and clogged by system media.

- Straight through flow path ideal for systems having “dirty” and viscous system media where rodding may be required.

- Choice of Acetal, PFA or Peek seats.

- Stainless steel handle locates precisely in the stem to stay tight.

Specifications

- Temperature: -65 to 600° F (-53 to 315° C)

- Pressure: up to 6000 psig (413 bar)

- Valve Orifice Sizes: 0.187 and 0.250

- Flow coefficient (Cv): up to 1.65

Resources

- Select Rising Plug and Gauge Valves for your applications.

- Download the LP Series Rising Plug and Gauge Valves Catalog.

Options

- Body and bonnet materials: 316 stainless steel and alloy 400

- Seat materials: Acetal, PFA and PEEK

- Packing Material: PTFE and PEEK (with PEEK seat only)

- End Connections

- Inlet: 1/4 and1/2 in. FNPT and 1/4, 1/2 and 3/4 in. MNPT

- Socket weld and butt weld ends are availabe

- Extended inlets available up to 6 in.

- Outlet/Ports: 1/4 and 1/2 in. FNPT

- Inlet: 1/4 and1/2 in. FNPT and 1/4, 1/2 and 3/4 in. MNPT

- Sizes: 1/4, 1/2 in to 3/4 in. inlets and 1/4 and 1/4 in. outlets.

- Extended Inlets (Lagging): 2, 4 and 6 in.

- Panel Mounting

- Specially Cleaning: Compliance with ASTM G93 Level C and CGA G-4.1, Cleaning Methods and Cleanliness Levels for Material and Equipment Used in Oxygen-Enriched Environments. To specify, add -XP98 to the part number.

- Sour Gas: SSP offers four confi gurations to meet the requirements in ANSI/NACE MR0175/ISO 15156- 3 and NACE MR0103/ISO 19745.

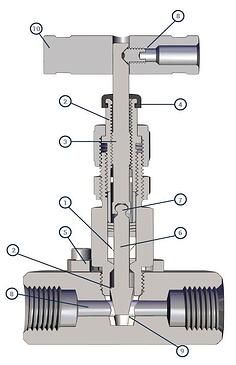

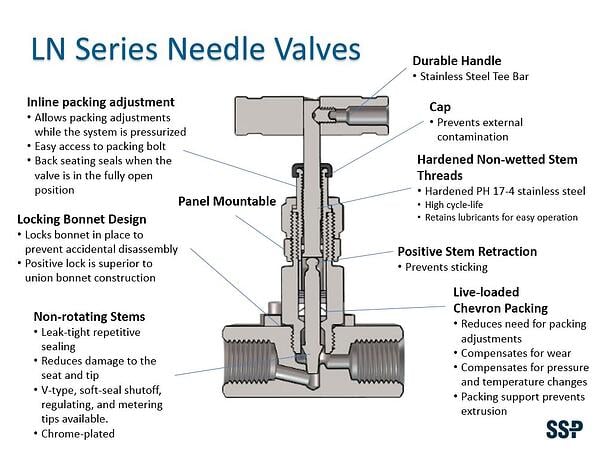

Needle Valves | LN - HLN Series Locked Bonnet Needle Valves

LN Series needle valves are designed for the special temperature, pressure and compatibility required in many severe service applications in the oil & gas, chemical/petrochemical, and power industries. The locked bonnet and live-loaded chevron packing are ideal for applications having high vibration and dynamic pressures and temperatures. LN Series valves are also available in gauge and block & bleed valve configurations. HLN Series needle valves are designed for pressures up to 10,000 psig (689 bar)

LN Series Needle Valves

Specifications

- Temperature: -100 to 1200° F (-73 to 648° F)

- Pressure: up to 6000 psig (413 bar)

- Valve Orifice Sizes (max. Cv):

- LN4: 0.156 orifice (0.34)

- LN6: 0.250 orifice (0.85)

- LN8: 0.437 orifice (2.18)

- Patterns: Straight, angle, gauge, and block and bleed

- Body Materials: 316 SS, Alloy 400, and C-276

- Packing Materials: PTFE (Standard) and flexible graphite. PEEK packing is available for LN6 and HLN6 valves only.

- Stem types: Non-rotating vee, soft seal (PCTFE), regulating and metering

- End Connection Types: Duolok, Unilok and Griplok tube fittings, NPT and BSP pipe ends, SAE straight thread, and tube and pipe socket and butt weld

- End Connection Sizes

- Fractional: 1/8 to 1 in.

- Metric: 6 to 12 mm (Duolok tube fittings only)

Resources

- HLN Series Needle Valves

- LN Series Needle Valves – Straight

- LN Series Needle Valves – Angle

- Download the LN & HLN Series Needle Valves Catalog

Features

NEW! HLN Series 10K Needle Valves

Specifications

- Temperature: -100 to 1200° F (-73 to 648° F)

- Pressure: up to 10000 psig (689 bar)

- Valve Orifice Sizes (max. Cv):10K Needle Valves Severe Service

- HLN4: 0.156 orifice (0.34)

- HLN6: 0.250 orifice (0.85)

- Patterns: Straight

- Body Materials: 316 SS

- Packing Materials: PTFE (Standard), PEEK, and flexible graphite.

- Stem types: Non-rotating vee, regulating and metering

- End Connection Types: Duolok, Unilok and Griplok tube fittings, NPT and BSP pipe ends, and tube and pipe socket weld

- End Connection Sizes

- Fractional: 1/4 and 1/2 in.

- Metric: 6 and 12 mm (Duolok tube fittings only)